Pigging system pharmaceuticals: Enhancing Efficiency and Safety

In the pharmaceutical industry, maintaining product quality and ensuring compliance with safety and regulatory standards are paramount. One of the key technologies that support these goals is the pigging system. Pigging systems are widely used in various industries to clean, separate, and inspect pipelines. In pharmaceuticals, where contamination can have serious health consequences, these systems play a critical role in safeguarding product integrity, improving operational efficiency, and reducing waste. In this article, we will explore the importance of pigging system pharmaceuticals their applications, and how they contribute to the success of pharmaceutical operations.

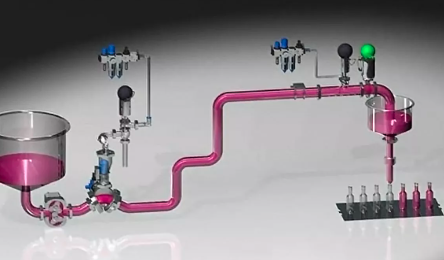

What is a Pigging System?

A pigging system is a pipeline maintenance solution that uses a device, called a “pig,” to travel through pipes to perform various tasks, such as cleaning, separating products, and inspecting the pipeline. These pigs are designed to remove residual materials that might otherwise be left behind, ensure that different products do not mix, and check the integrity of the pipeline. The term “pig” is an acronym for Pipeline Inspection Gauge, and it has become a standard tool in the pharmaceutical industry for maintaining pipeline hygiene and ensuring product quality.

In the pharmaceutical industry, pigging systems are crucial because they help transport raw materials, intermediates, and finished products without contamination, ensuring that drugs are safe and effective for consumers. These systems are used in pharmaceutical manufacturing plants that handle large volumes of liquid or semi-liquid products, such as syrups, solutions, and suspensions.

Why is Pigging Important in the Pharmaceutical Industry?

1. Preventing Cross-Contamination

One of the main challenges in pharmaceutical manufacturing is preventing cross-contamination between different products. The ingredients used in pharmaceuticals are highly specific, and even small traces of one product can compromise the quality of another. This is particularly true in the production of different drugs or formulations, where contamination could result in serious health risks for patients.

Pigging systems help prevent this risk by ensuring that pipelines are thoroughly cleaned between product batches. By using pigging systems, manufacturers can remove all traces of the previous batch before starting the next one. For example, if a plant is switching from manufacturing a pain relief medication to a cough syrup, the pigging system can ensure that no residue from the pain relief product remains in the pipeline, preventing contamination of the new product.

Read also: What Are the Top Strategies to Increase Revenue for Your Remodeling Business?

2. Maintaining Hygiene and Compliance

The pharmaceutical industry is heavily regulated, with stringent guidelines for manufacturing processes. The Good Manufacturing Practice (GMP) guidelines, for example, set forth rules regarding cleanliness and safety in drug production. Pigging systems help manufacturers comply with these regulations by ensuring that their pipelines remain free from residues and contaminants. Clean pipelines are essential for maintaining high standards of hygiene, which are critical to ensuring that drugs are safe for consumption.

Regular cleaning of pipelines is also necessary for preventing microbial growth and product degradation, which can affect the efficacy of pharmaceutical products. By using a pigging system, manufacturers can automate and optimize the cleaning process, reducing the need for manual intervention and improving overall cleanliness.

3. Improving Operational Efficiency

In pharmaceutical manufacturing, time is money. Reducing downtime between product runs, improving process efficiency, and ensuring smooth transitions between batches are key to improving productivity and reducing costs. Pigging systems enhance operational efficiency by streamlining the cleaning process, ensuring that the pipeline is ready for the next batch with minimal downtime.

Without pigging, cleaning a pipeline might involve disassembling parts of the system, manually cleaning the interior, and waiting for components to dry or be sanitized. With a pigging system, this process is automated, and the cleaning process can be completed much faster, allowing for quicker turnarounds between product batches. The ability to maintain continuous production without unnecessary delays is crucial in a competitive industry like pharmaceuticals.

4. Reducing Product Waste

Product waste is a significant concern in the pharmaceutical industry, especially when dealing with expensive raw materials or high-value drugs. Without a pigging system, residual product left in the pipelines after each batch can be lost, leading to substantial waste and increased production costs.

Pigging systems are designed to recover as much of the product as possible, reducing waste and improving the overall yield. The pigs are designed to push the remaining product out of the pipeline and into storage tanks, ensuring that the majority of materials are recovered. This not only minimizes waste but also helps manufacturers get the most out of their raw materials, ultimately contributing to cost savings and better resource utilization.

5. Ensuring Product Integrity

Pharmaceutical companies must ensure that their products meet rigorous quality standards. The slightest contamination or degradation in quality can render a batch unsafe for use, leading to costly recalls and reputational damage. Maintaining the integrity of each batch is crucial for both the safety of patients and the financial health of the business.

Pigging systems help ensure product integrity by eliminating the risk of contamination from previous batches and ensuring that the pipeline is thoroughly cleaned and sanitized. This prevents cross-contamination and preserves the quality of the drugs being produced. For example, in the production of injectable solutions, even small amounts of residue left in the pipeline can result in contamination, which could have serious consequences. A pigging system effectively removes this residue and ensures that only the correct product is produced.

6. Enhanced Traceability and Compliance Reporting

Another key benefit of pigging systems in pharmaceuticals is the enhanced traceability and reporting capabilities they provide. Many pigging systems are equipped with advanced sensors and data collection tools that record the cleaning process, allowing manufacturers to track and document every cleaning cycle. This data can be used for compliance reporting, ensuring that manufacturers are adhering to regulatory requirements.

In addition, the ability to track each cleaning cycle and the effectiveness of the cleaning process provides manufacturers with the information needed to optimize their operations and ensure consistent product quality. This traceability feature is especially important in the pharmaceutical industry, where documentation and proof of compliance are crucial for regulatory audits.

7. Environmental Benefits

Pigging systems can also provide environmental benefits by reducing the amount of cleaning chemicals used in the cleaning process. Traditional cleaning methods often involve the use of harsh chemicals and large amounts of water, which can have a negative environmental impact. With pigging systems, the need for excessive cleaning agents is minimized, as the pigs effectively remove residue from the pipeline without the need for chemical cleaning. This helps pharmaceutical companies reduce their environmental footprint and adhere to sustainable practices.

Conclusion

The pigging system pharmaceuticals is an invaluable technology that helps improve efficiency, ensure product quality, and reduce waste. By preventing cross-contamination, maintaining hygiene standards, and enhancing operational efficiency, pigging systems are an essential part of pharmaceutical manufacturing processes. As the pharmaceutical industry continues to grow and face increasing demand for safe, high-quality products, the role of pigging systems will become even more critical. Investing in pigging technology is a proactive step toward improving operational performance, meeting regulatory requirements, and ensuring that products are safe for consumers.