Foam Protective Packaging: The Ultimate Solution for Efficient Product Transit

Foam protective packaging is a critical component in modern logistics, ensuring the safe transportation and storage of a variety of products. Whether it’s fragile electronics or expensive machinery, foam protective packaging serves as a reliable shield against impact, moisture, and temperature changes. By absorbing shocks and preventing damage, foam packaging significantly reduces the risks associated with shipping delicate items. This article explores the importance of foam protective packaging, its key benefits, types, and how it can be customized to fit specific product needs.

What is Foam Protective Packaging?

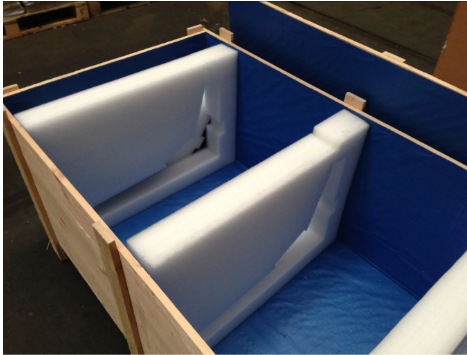

Foam protective packaging is a material solution designed to safeguard products from physical damage during transit or storage. It is commonly used in industries such as electronics, automotive, healthcare, and industrial equipment due to its excellent cushioning and protective properties. One of the most popular forms of foam used for packaging is polyethylene foam, known for its durability, resilience, and cost-effectiveness.

Polyethylene foam is a cross-linked foam that offers superior protection for high-value or delicate products. Its shock-absorbing properties make it ideal for multi-use applications, ensuring products remain undamaged even after repeated impacts. Polyethylene foam protective packaging is especially useful for factory transit, reusable packaging, and tool packs where repeated handling and multi-trip use are common.

Benefits of Foam Protective Packaging

1. Superior Shock Absorption

One of the standout features of foam protective packaging is its ability to absorb and distribute impact forces. The foam structure consists of numerous closed cells that act as tiny shock absorbers, reducing the risk of damage during transportation. This makes it an ideal solution for packaging delicate or fragile items that require careful handling. For instance, polyethylene foam protective packaging is highly effective in protecting products from multiple drops without degrading over time, providing consistent and dependable protection.

2. Moisture and Chemical Resistance

Foam protective packaging, particularly polyethylene foam, is resistant to moisture and chemicals, making it a reliable option for products that need protection from environmental factors. This is particularly important for electronics, such as smartphones or computer components, which can be damaged by moisture during shipping or storage. By creating a protective barrier, foam packaging helps prolong the lifespan of sensitive products.

3. Versatility in Applications

Foam protective packaging is used in a wide range of industries, from automotive parts to healthcare devices. Its versatility is due to its customizable properties, where the foam can be cut, molded, or shaped to fit the specific requirements of different products. Polyethylene foam, for example, is available in various colors such as black, white, blue, and anti-static pink, allowing for further customization based on industry needs. Moreover, specialized foams like Nomafoam and Zotefoam are used for more niche applications, providing advanced protection where needed.

4. Reusability and Cost Efficiency

Although polyethylene foam protective packaging may be more expensive than alternatives like polystyrene, it offers long-term cost savings through its durability and reusability. Products packaged with this foam can withstand multiple shocks without the material breaking down, making it ideal for multi-trip applications. This means businesses can reduce packaging waste and minimize costs associated with constantly replacing damaged goods.

Types of Foam Protective Packaging

1. Polyethylene Foam Protective Packaging

Polyethylene foam is a cross-linked material known for its strength and shock absorption capabilities. It is widely used in packaging high-value items that require extra protection during transit. This type of foam is particularly beneficial for reusable packaging solutions, as it retains its cushioning properties even after multiple impacts. Available in various densities and colors, polyethylene foam protective packaging is customizable to suit different product needs.

2. Polystyrene Foam for Toolboxes

Polystyrene foam, especially Expanded Polystyrene (EPS), is a popular choice for toolboxes and industrial packaging. EPS is lightweight, cost-effective, and provides excellent protection against shock and environmental factors. Its closed-cell structure ensures moisture resistance, making it ideal for use in outdoor or industrial environments. Polystyrene foam can also be molded into custom shapes, providing a snug fit for tools and equipment.

3. Specialized Foam Packaging

In addition to standard polyethylene and polystyrene foam, specialized foams such as Nomafoam, Plaztazote, and Zotefoam are used for more specific applications. These foams are designed to meet unique product requirements, often requiring specialized tooling. For example, Zotefoam is known for its lightweight properties and excellent thermal insulation, making it suitable for protecting temperature-sensitive products like medical devices or aerospace components.

Read Also: Luxurious Comfort: Experience Unmatched Rest with Hotel Suite White Goose Pillows

Customization Options for Foam Protective Packaging

One of the greatest advantages of foam protective packaging is its ability to be tailored to meet specific product needs. Manufacturers can produce foam inserts, trays, or fitments that match the shape and size of the items being shipped. This ensures a snug fit, providing maximum protection and minimizing movement within the packaging. Custom foam packaging solutions are commonly used in industries like electronics, automotive, and healthcare, where precision is key to ensuring the safety of high-value products.

Foam protective packaging can also be customized with various add-ons such as anti-static properties, which are crucial for packaging electronic components. Anti-static foam prevents the build-up of static electricity, protecting sensitive electronics from potential damage during transit.

Applications of Foam Protective Packaging

1. Electronics Industry

The electronics industry is one of the largest users of foam protective packaging. Products like smartphones, laptops, and delicate computer components require protection from shock, moisture, and static electricity. Foam packaging provides a cushioning barrier that absorbs impact and prevents damage during shipping. Polyethylene foam protective packaging is often used due to its superior shock absorption and moisture resistance, ensuring electronic devices arrive at their destination in perfect condition.

2. Automotive Parts

Automotive components, especially delicate or expensive parts, benefit from foam protective packaging. Polyethylene foam is widely used in the automotive industry to protect parts from damage during transportation and storage. Its ability to absorb impact while maintaining durability makes it an ideal choice for multi-trip packaging solutions, ensuring that parts remain undamaged even after repeated handling. In sectors like automotive, integrating secure Autotransport solutions with protective packaging ensures that both individual parts and complete vehicles arrive undamaged and on time.

3. Healthcare and Medical Devices

Healthcare products, including medical devices and instruments, require specialized protection during transit to prevent contamination or damage. Foam protective packaging provides the cushioning and moisture resistance necessary to safeguard these sensitive items. Polyethylene foam is commonly used to create custom packaging solutions for medical devices, ensuring they remain sterile and intact during shipping.

Conclusion

In today’s fast-paced world of logistics and product transportation, ensuring that goods arrive safely is more important than ever. Foam protective packaging offers a versatile, reliable, and cost-effective solution for protecting a wide range of products. From polyethylene foam’s shock absorption and moisture resistance to its customizable features, foam protective packaging ensures that fragile, high-value, or sensitive items remain safe during transit. Whether used in the electronics, automotive, or healthcare industries, foam protective packaging delivers unparalleled protection and peace of mind.

By utilizing foam protective packaging, businesses can reduce the risk of product damage, minimize returns, and enhance customer satisfaction. From start to finish, foam protective packaging is the ultimate solution for ensuring products arrive in perfect condition, every time.