Flange Marking Machine Manufacturer: Key Insights and Benefits

Introduction

In industries such as manufacturing, construction, oil, and gas, flanges are essential components that play a critical role in connecting pipes, valves, pumps, and other equipment in piping systems. These parts are designed to bear significant pressure, and their proper identification is crucial for installation, maintenance, and inspection purposes. To ensure precise and lasting identification, flange marking machines are used to engrave important information on the surface of flanges.

The use of a flange marking machine allows manufacturers to efficiently mark flanges with vital details such as part numbers, material specifications, serial numbers, and quality control information. This article explores the role of flange marking machines, the technology behind them, and why selecting the right flange marking machine manufacturer is crucial for businesses.

What is a Flange Marking Machine?

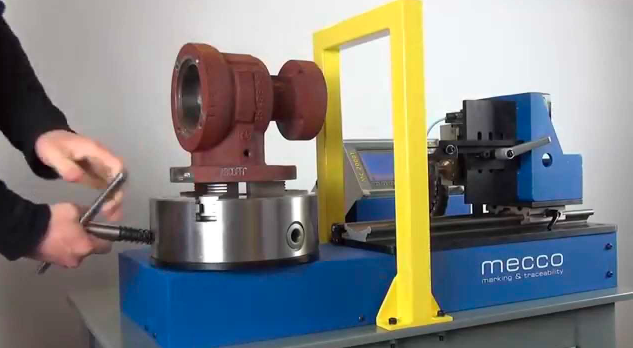

A flange marking machine is a specialized device designed to mark flanges with essential information that ensures traceability, compliance, and operational safety. The marking process involves engraving or printing text, logos, part numbers, material grades, and other vital identifiers onto the surface of the flange.

Why Marking Flanges is Essential

Marking flanges is an essential process for several reasons:

1. Traceability

Properly marked flanges enable easy traceability. Flanges are often used in critical systems, where identifying the material grade, certification details, and manufacturing history is crucial. A well-marked flange can be traced back to its origin, helping prevent the use of faulty or substandard parts.

2. Compliance with Industry Standards

Flanges must comply with industry standards, such as those set by the American Society of Mechanical Engineers (ASME), the American Petroleum Institute (API), or the International Organization for Standardization (ISO). Marking flanges with the correct standards, material specifications, and part numbers ensures compliance and minimizes the risk of errors during installation or inspection.

3. Maintenance and Inspection

Flanges undergo regular inspections during their service life to ensure their integrity. By marking flanges with vital information such as maintenance history, inspection dates, and part numbers, workers can easily identify the flange’s specifications and track its maintenance and operational status.

4. Operational Safety

In industries where flanges are subjected to high pressure or extreme temperatures, having clear and accurate markings on the flange ensures that operators can make informed decisions regarding installation, handling, and replacement. Proper flange marking can significantly reduce the risk of accidents caused by incorrect or outdated parts.

Types of Flange Marking Machines

There are different types of flange marking machines available, each suited to specific applications and materials. These machines vary in terms of the technology they use to mark flanges, and each has its advantages based on the specific needs of the manufacturer.

1. Laser Marking Machines

Laser marking machines use focused laser beams to engrave permanent marks onto the flange’s surface. The laser interacts with the material to create precise, clean, and highly durable markings.

Advantages of Laser Marking:

- High Precision: Laser marking offers extreme precision and can create fine, intricate markings even on complex surfaces.

- Durability: The markings are highly resistant to wear, corrosion, and high temperatures.

- Non-contact Process: The laser beam does not physically touch the flange, reducing the risk of damaging delicate surfaces.

- Customization: Laser marking allows manufacturers to easily customize the markings with logos, part numbers, and other specific details.

Laser marking is ideal for high-precision applications, including aerospace, automotive, and heavy industries.

2. Dot Peen Marking Machines

Dot peen marking machines use a stylus to strike the surface of the flange, creating a series of small dots that form characters, numbers, or symbols. The stylus’s impact creates a deep, permanent indentation that ensures the marking will endure through various industrial conditions.

Advantages of Dot Peen Marking:

- Cost-Effective: Dot peen marking machines are more affordable than laser marking systems, making them ideal for high-volume production.

- Versatility: These machines can work on a wide range of materials, including metals, alloys, and even plastics.

- Durability: The markings are deeply engraved, making them resistant to wear, corrosion, and environmental exposure.

- Speed: Dot peen marking is faster than many other engraving methods, which is beneficial in a fast-paced production environment.

Dot peen marking is commonly used in manufacturing, automotive, and construction industries, where efficiency and cost-effectiveness are key.

Read also: What Are the Key Benefits of PowerPOD for Businesses?

3. Mechanical Engraving Machines

Mechanical engraving machines use a rotating cutting tool to carve markings into the surface of the flange. The tool physically cuts into the material, ensuring deep, permanent marks that can withstand harsh industrial conditions.

Advantages of Mechanical Engraving:

- Long-Lasting Markings: Mechanical engraving creates deep, durable marks that are resistant to abrasion, wear, and corrosion.

- Precision: It offers high accuracy and is especially effective for marking hard materials like steel and stainless steel.

- Customization: Engraving allows for customized designs, logos, and part numbers to be marked on the flange.

Choosing the Right Flange Marking Machine Manufacturer

Selecting the right flange marking machine manufacturer is essential for businesses seeking to optimize their production processes and ensure high-quality marking on flanges. Here are some factors to consider when choosing a manufacturer:

1. Machine Quality and Durability

The marking machine should be built to last and capable of withstanding the demanding conditions of industrial environments. Look for a manufacturer that offers high-quality machines made from durable materials and components.

2. Customization Options

A good flange marking machine manufacturer should be able to offer machines that can handle customized marking requirements, such as logos, barcodes, or part numbers. Customization ensures that the machine can meet the unique needs of your production line.

Conclusion

A flange marking machine is an essential tool for manufacturers across various industries, ensuring that flanges are marked with the necessary information for traceability, compliance, and operational safety. By selecting the right flange marking machine manufacturer, companies can invest in a reliable, efficient, and durable solution that improves production processes and ensures that each flange meets industry standards.